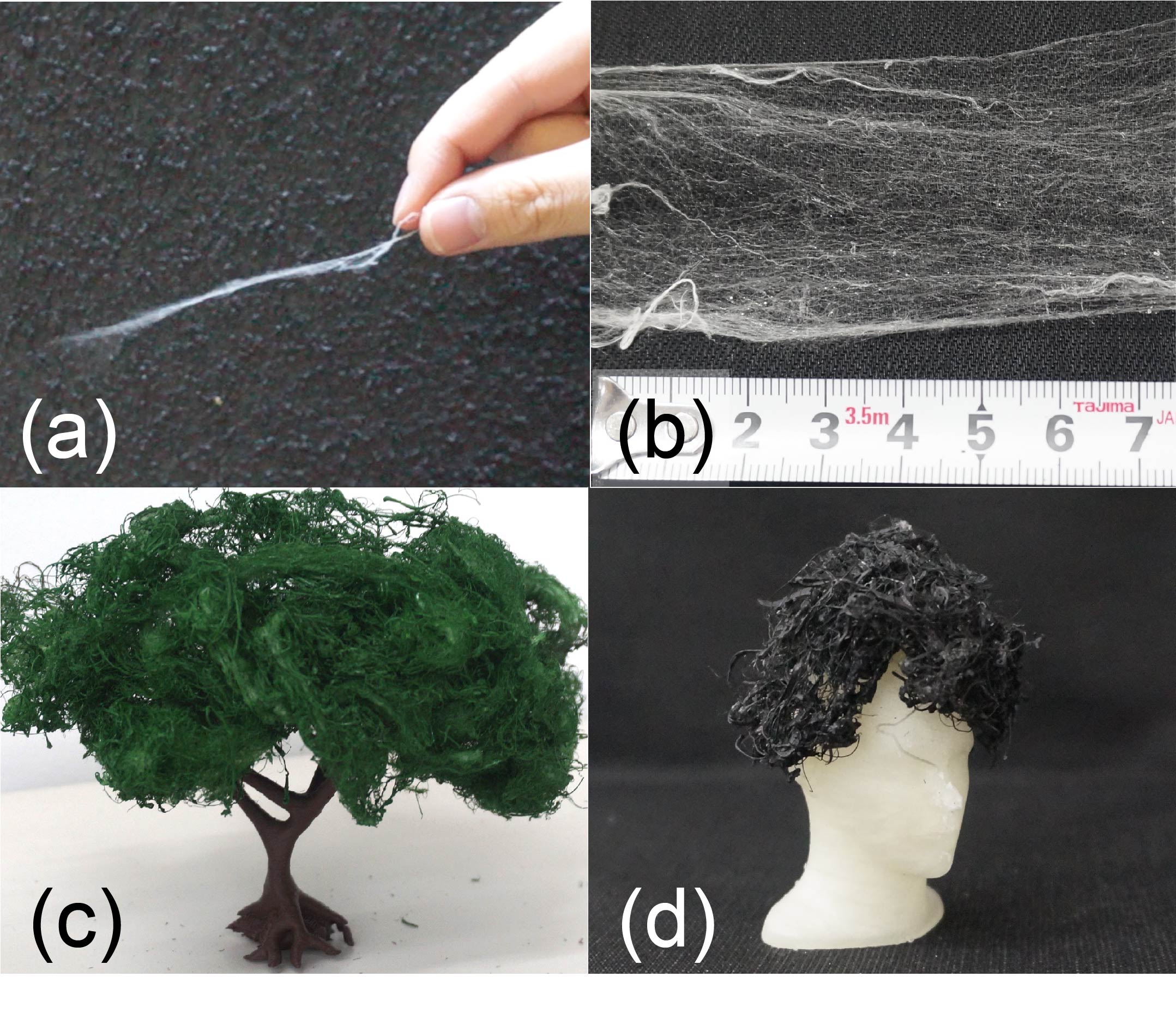

The development of personal fabrication technologies has enabled end users to model and prototype desired objects. 3D printing technologies have eased our access to solid models, however, it is still a challenge to develop thin fibers rapidly at personal levels that may help enriching textures of models. We propose a system and method inspired by cotton candy making, which uses rotary jet-spinning to extract thin plastic fibers at high speed. We report our exploration of the proposed method where we studied various plastic materials, the effects of the rotation speed, and the hole size of the fiber exit. The method allows plastic fibers to be extracted at micro-scale, and we propose various examples of use cases. Our approach can be used in combination with traditional 3D printing techniques, where soft and/or hairy models are required to design the texture of a 3D model.

- Natsuki Hamanishi*, Michinari Kono*, Shunichi Suwa, Takashi Miyaki, and Jun Rekimoto. 2019. Fibritary: Rotary Jet-Spinning for Personal Fiber Fabrication. In Extended Abstracts of the 2019 CHI Conference on Human Factors in Computing Systems (CHI EA ’19), ACM, New York, NY, USA, 6 pages. DOI: https://doi.org/10.1145/3290607.3312934 (Peer Review, Late Breaking Work) *Contributed Equally